Answer

Sep 09, 2024 - 10:28 AM

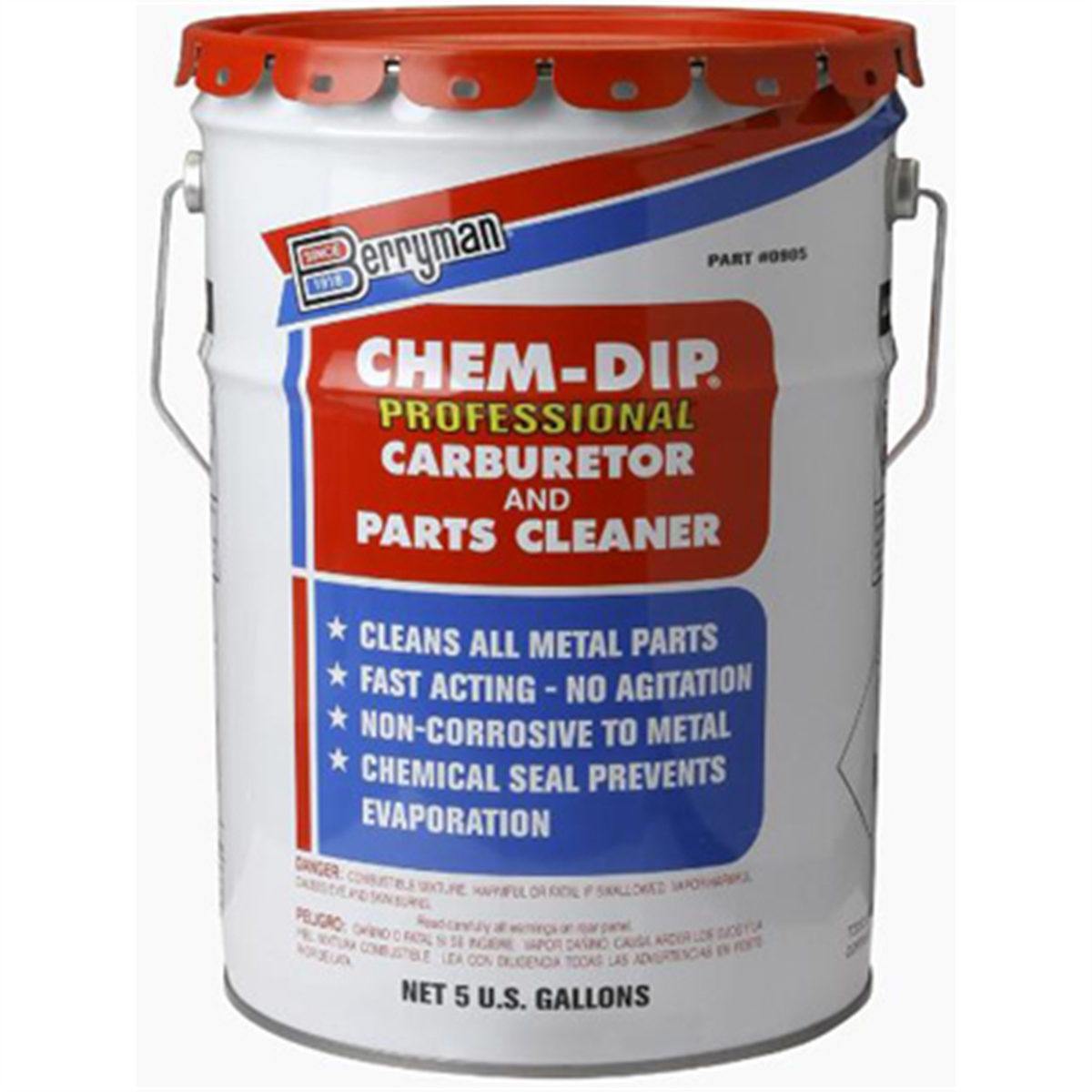

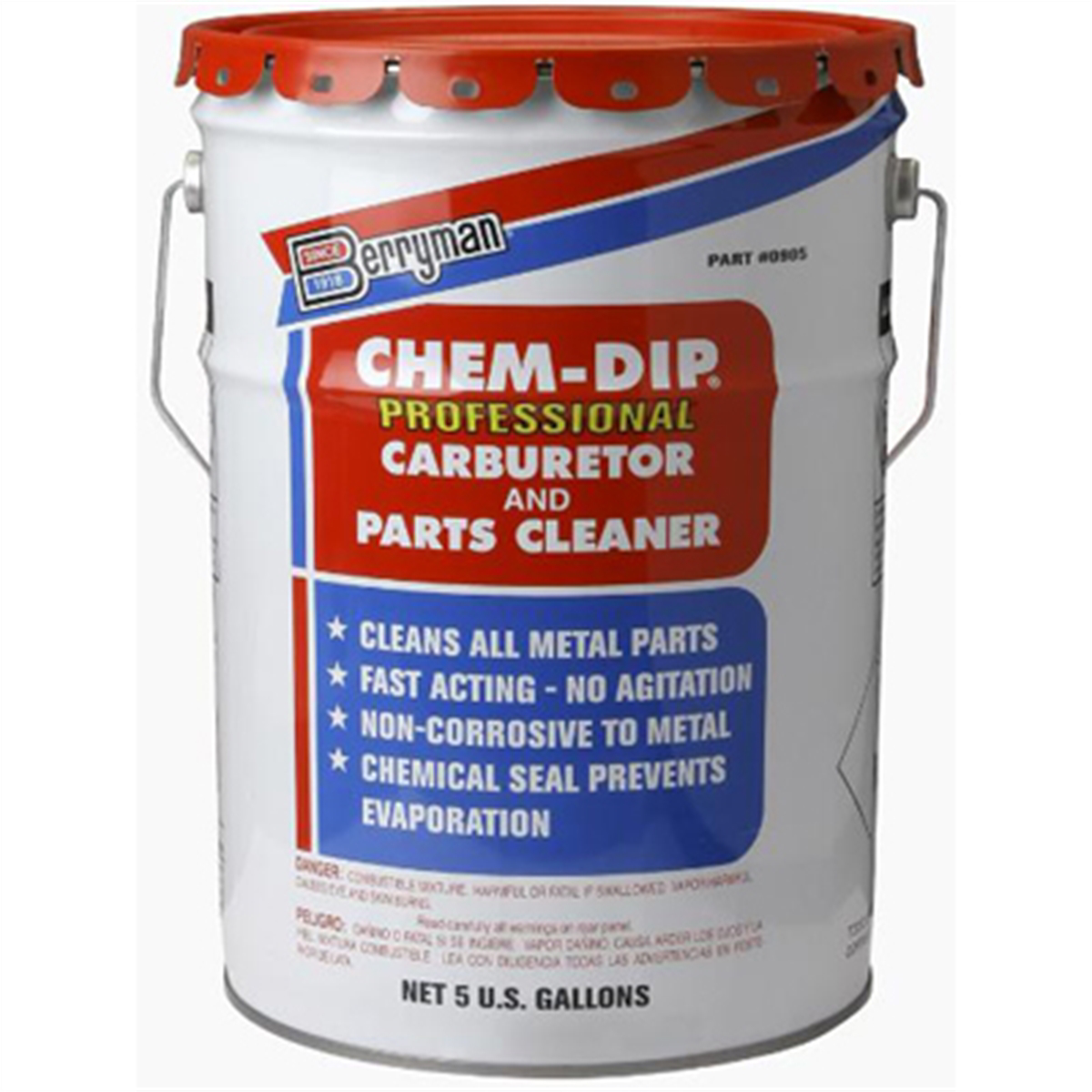

When using 905 Chem Dip Professional Parts Cleaner, choosing the right container is important for safety and effectiveness. Here are some suitable container options:

-

Metal Containers: Many industrial-grade parts cleaners are stored in metal containers, like steel drums or cans. These are resistant to the chemical properties of the cleaner and are often used in professional settings.

-

Plastic Containers: High-density polyethylene (HDPE) or other chemical-resistant plastics can also be used. Ensure that the plastic is compatible with the cleaner to avoid any chemical reactions or degradation of the container.

-

Cleaning Tanks: For larger volumes or industrial use, dedicated parts cleaning tanks or immersion tanks are ideal. These are specifically designed to hold and use parts cleaners and often come with features like built-in heaters and agitation to enhance cleaning efficiency.

-

Airtight or Sealable Containers: To prevent evaporation and maintain the effectiveness of the cleaner, use containers with tight-sealing lids. This helps in preserving the cleaner and avoiding exposure to air.

-

Non-reactive Containers: Ensure that any container used is made from materials that do not react with the chemicals in the parts cleaner. Avoid using containers made from materials like aluminum or other metals that may corrode or react with the cleaner.

Always follow the manufacturer’s guidelines for the container material and type to ensure safety and maintain the effectiveness of the cleaner.

Add New Comment